FORESIGHT IS 20/20.

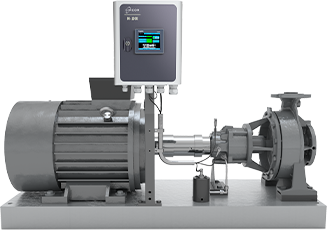

With IN-1000 condition monitoring, you'll be able to assess expected performance on key indicators

such as leak detection and bearing temperature, vibration, suction and discharge pressure against

actual performance – and detect anomalies. So you can remedy dangerous seal leaks even before they

happen.

WANT TO LEARN MORE?

To find out what IN-1000 condition monitoring can do for you, fill out the form

on the right to get in touch with your distributor.

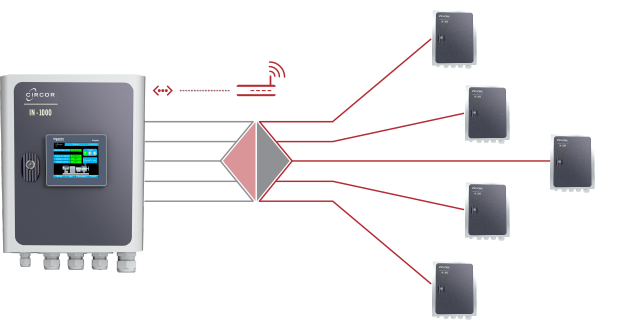

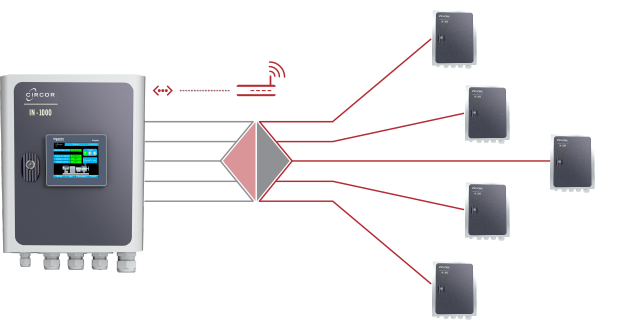

11 PUMPS IN THE PALM OF YOUR HAND.

IN-1000 is a retrofit modular solution for central condition monitoring. With one master and up to

10 satellite modules per network, it is possible to monitor as many as 11 pumps. Built-in features include:

- Two-level warning and alarm system

- Logging of sensor data

- Remote monitoring with Vijeo Design'Air smartphone app

IN-1000. A SMARTER TOOL

FOR SMARTER DECISIONS.

With the IN-1000 condition monitoring solution, you can keep your facility up and running at its best, reducing total cost of ownership:

- Steer clear of consequential damages from dangerous seal leaks and worn-out bearings

- Avoid unplanned production downtimes

- Pre-plan maintenance and repairs

- Extend maintenance intervals

- Potentially reduce insurance premiums as your overall safety profile improves

DESIGNED TO KEEP SMALL PROBLEMS FROM BECOMING MAJOR DISASTERS.

When you're handling combustible fluids, you can't afford the trouble caused by an unmonitored mechanical seal leak. What you can afford is the safe and cost-effective operation of your plant with an aftermarket investment in the IN-1000, the market's most advanced solution for condition monitoring of thermal transfer pumps.

WANT TO LEARN MORE?

More information can be found by downloading the brochure or article found below.

Condition Monitoring Brochure

Condition Monitoring Broschure (Deutsch)

Odenwald Faserplattenwerk Case Study